Welding and maintenance

French manufacturer of machinery and equipment

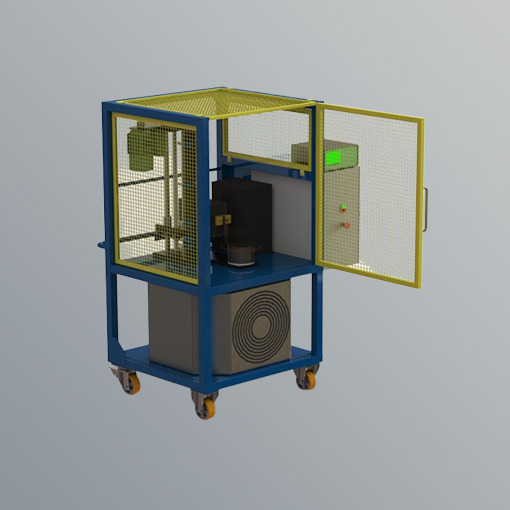

S12 – PlasmaBox

S12 – PlasmaBox is a micro-plasma welding solution for localized repair of moulds and accessories (mould neck rings, edges and cavities) using nickel rod.

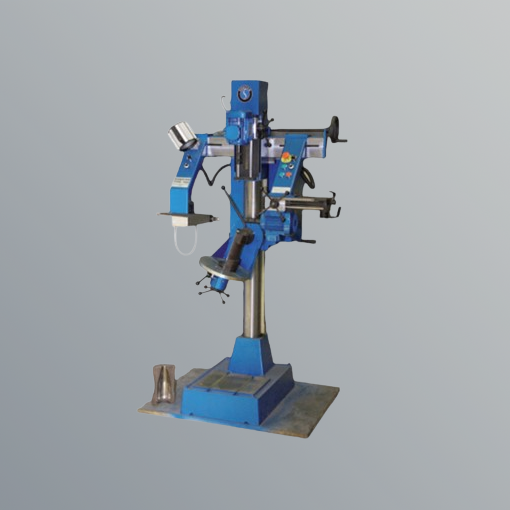

RS6 – Mould Drilling

RS6 – Mould Drilling is the ideal equipment for drilling and unblocking vent holes in internal and external glass moulds cavities.

The axis on the left makes it easy to drill the smallest holes without the risk of breaking the drilling tool, thanks to its perpendicularity with the mould cavity.

The right-hand axis and the vertical axis are used for drilling and tapping in the mould’s external cavity.

The three axes allow existing holes to be cleaned.

RS7 – Mould Grinding

RS7 – Mould Grinding is a solution for surface and hollow grinding of moulds. Hollow grinding is carried out by copying a template (scale of 1/10).

Thanks to its jointer assembly and magnetic holder, the mould is perfectly positioned.

The graduated vernier and diamond-cut grinding wheel enable to remove material with precision and obtain a flat and homogeneous surface.

RS7 is equipped with lubrification to cool the mould and improve surface.

S11 – SoniHeat

S11 – SoniHeat is a rapid induction preheating machine for moulds and accessories.

S14 – SoniArm

S14 – SoniArm is a lifting device for handling heavy magnetizable loads (moulds and accessories).